Many industrial procedures deal with mixtures that contain liquids as well as suspended solids. The need for clear liquid output and controlled solid waste becomes more pressing when production demands increase. Traditional filtration setups may clog, slow down or require constant supervision. An ideal Filter Press System changes that experience by supporting consistent separation performance with stable cycle timing.

This guide explains how a filter press works, what components form the system, the available types and the industries that rely on it.

What is a Filter Press?

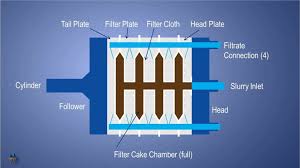

A Filter Press System separates solids from liquids through filtration driven by pressure. The pulp flows into chambers formed between closely arranged filter plates. Each plate carries filter cloth that captures the solid material while allowing the liquid to pass through.

Once the pressure increases inside these chambers, the solids compress into what is known as a filter cake. The liquid exits the system as filtrate. This approach supports consistent removal of solids and delivers a drier cake compared to many other filtration setups.

Plants value the structure of a Filter Press System because it supports both reliability and compact design. Facilities with limited operational space benefit from the stacked plate configuration. The filtration outcome remains stable across repeated cycles, which helps maintain product quality and waste handling efficiency.

How Does a Filter Press Work?

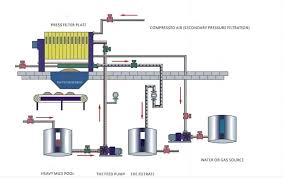

The working procedure begins with the slurry feed pump. The slurry enters the plate chambers at a controlled rate. The plates remain tightly pressed together while keeping the chamber sealed.

The filter cloth holds the solid particles as the slurry fills the chamber while the liquid phase moves through the cloth fibers. Pressure increases gradually. The system continues to push liquid out while solids build into a cake. Once no more liquid exits, the cycle reaches completion. The plates then open. The cake falls out or is removed.

A well-managed Filter Press System depends strongly on pressure control, feed consistency, and cycle timing. When these factors align with the material characteristics, filtration becomes a predictable and stable process. That reliability explains why many industries rely on this system for daily operations rather than occasional use.

Components of a Filter Press

A Filter Press System contains several key elements that work in coordination.

- Frame- Holds the structure together and supports the load created by pressure during filtration.

- Filter Plates- Form the chambers and give shape to the cake.

- Filter Cloth- Determines how effectively solids separate from liquid.

- Hydraulic System- Opens and closes the press and controls plate movement.

- Feed Pump- Supplies the slurry to the chambers.

Each element influences performance. The frame must maintain structural stability. Plates must remain aligned under pressure. Cloth selection often has the strongest effect on filtrate clarity. The feed pump manages flow rate and pressure stability. The filtration result remains dependable when these parts work together cleanly.

Types of Filter Press System

Different facilities require different degrees of control and labor involvement.

- A manual Filter Press System suits small production lines or intermittent operation. Operators open the plates, remove cake, and reset the system by hand. It is cost-effective for lower volume needs.

- A semi-automatic system reduces physical strain by using mechanical assistance for tasks such as plate shifting. Operators still supervise the cycle but do not perform as many repetitive actions.

- A fully automatic Filter Press System manages the entire cycle without continuous human involvement. It opens and closes the plates, handles feeding, and manages cake discharge. Plants that operate continuously or at high volume often select this configuration because it supports predictable output and reduces labor load.

Types of Filter Plates: Recessed, Membrane, and Plate & Frame

Plate selection influences filtration performance as much as automation does.

- A recessed plate design forms chambers where the cake collects in a uniform layer. These plates support reliable cake formation and suit many wastewater and general process applications.

- A membrane plate configuration includes a flexible layer that expands after initial cake formation. This expansion squeezes the cake further and removes more moisture. A membrane-style Filter Press System often appears in industries that require drier solids to reduce disposal volume or improve handling.

- A plate and frame setup places filter media between alternating plates and frames. This arrangement focuses on clear filtrate output and suits environments that prioritize liquid clarity over cake dryness. The selection depends on the priorities of the process rather than a universal standard.

Industrial Applications

A Filter Press System appears across industries where separation influences product quality or waste management.

- Mining operations use it to recover valuable minerals and reduce tailings moisture.

- Chemical plants rely on it to maintain controlled filtration during reaction or precipitation steps.

- Food and beverage processors clarify liquids such as juices, syrupsor fermentation batches.

- Pharmaceutical environments use it for precise solid or liquid separation that supports downstream purity.

- Textile and metal finishing industries apply it in wastewater treatment stages to manage suspended solids.

- Municipal treatment plants use it to reduce sludge volume, lowering transportation and disposal requirements.

Its adaptability comes from the way the system finds it application across different industries while maintaining stable performance across repeated cycles.

Maintenance and Best Practices

The ongoing performance of a Filter Press System depends on consistent maintenance habits. Filter cloth requires regular cleaning to maintain porosity and prevent blinding. Plates benefit from inspection to confirm alignment and prevent leakage. The hydraulic system needs monitoring to maintain smooth opening and closing. Pumps should maintain stable flow and pressure output.

Selecting the correct cloth material for the particle size and chemical composition of the slurry plays a major role in how effectively the system runs. Plants that evaluate cloth wear, cake texture, and filtrate clarity at regular intervals often maintain higher uptime and fewer slowdowns.

Choosing the Right Filter Press for Your Application

Selecting a Filter Press System begins with a clear understanding of your slurry characteristics. Cake dryness requirements, available floor space, desired cycle time, daily throughput, and labor considerations guide the decision. Product testing often supports the final configuration. Different slurries behave differently under pressure, so trial runs help confirm suitable plate style, cloth type, and pump configuration.

Facilities that select based on real operating behavior rather than generic expectations often achieve smoother integration and more reliable long-term operation.

Conclusion

A Filter Press System supports controlled and consistent solid-liquid separation across many industries. Its structured plate design, pressure-based operation, and adaptable configurations allow plants to manage waste, recover materials, and maintain clear liquid output. With thoughtful selection and committed maintenance, the system remains reliable through daily operational demands and contributes to a more stable overall production environment.